Stainless simbi ndiro

Product Description

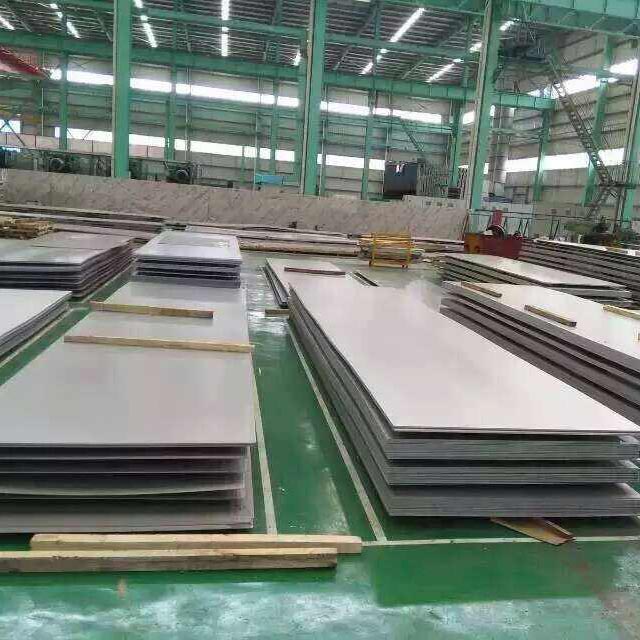

Zvinoenderana nemaitiro ekugadzira, kune marudzi maviri ekupisa uye kutonhora kukunguruka, kusanganisira 0.5-4 mm gobvu sheet uye 4.5-35 mm gobvu ndiro.

Zvinoenderana nehunhu hwesimbi, inogona kukamurwa kuita marudzi mashanu: austenite, austenitic-ferrite, ferrite, martensite uye kuoma kwemvura.

Shandisa zvakatipoteredza: takura kuora kwe oxalic acid, sulfate-ferric sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfate-copper sulfate, phosphoric acid, formic acid, acetic acid uye mamwe maasidhi.

Zvishandiso: zvinoshandiswa mumakemikari, chikafu, mushonga, pepa, mafuta, atomu simba uye mamwe maindasitiri, pamwe nezvikamu zvakasiyana uye zvikamu zvezvivakwa, kitchenware, tableware, mota uye midziyo yemumba.Kuti ive nechokwadi chekuti goho simba, tensile simba, elongation, kuoma uye zvimwe zvemichina zvinhu zvakasiyana-siyana Stainless simbi mahwendefa zvinosangana zvinodiwa, mahwendefa simbi anofanira kupinda annealing, mhinduro kurapwa, kuchembera kurapwa uye kumwe kupisa kurapwa asati kusununguka.

Hunhu hunodiwa: Stainless simbi ndiro ine yakatsetseka pamusoro, yakakwira plastiki, kuoma uye kusimba kwemagetsi, uye inoshingirira mukuora kweasidhi, alkaline gasi, mhinduro uye mamwe midhiya.Isimbi ine alloy isiri nyore kuita ngura, asi haina kana ngura zvachose.Kupokana kwekuora kwesimbi isina tsvina kunonyanya kuenderana nekuumbwa kwayo kwealloy (chromium, nickel, titanium, silicon, aluminium, nezvimwewo) uye chimiro chemukati.Basa guru ndiro chromium.Chromium ine kugadzikana kwemakemikari yakakwira, inogona kugadzira firimu rekufambisa pamusoro pesimbi, kutsaura simbi kubva kunze, kudzivirira ndiro yesimbi kubva kune oxidation, uye kuwedzera kusimba kwekuora kwesimbi ndiro.Mushure mekunge iyo passivation firimu yaparadzwa, iyo corrosion resistance inoderera.

Kuumbwa Kwemakemikari

| Kodhi yekudzidzisa yakabatana | Brand | Kuumbwa kwemakemikari (chikamu chehuwandu)/% | ||||||||||||||||||||||||||||||||||

| c | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | Zvimwe | ||||||||||||||||||||||||||

| S30408 | 06Cr19Ni10 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00 ~ 10.50 | 18.00 ~ 20.00 | 0.10 | |||||||||||||||||||||||||||

| S30403 | 022Cr19Nil0 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00 ~ 12.00 | 18.00 ~ 20.00 | 一 | 一 | 一 | |||||||||||||||||||||||||

| S30409 | 07Cr19Ni10 | 0.04~0.10 | 0.75 | 2.00 | 0.035 | 0.020 | 8.00 ~ 10.50 | 18.00 ~ 20.00 | 一 | |||||||||||||||||||||||||||

| $31008 | 06Cr25Ni20 | 0.04~ 0.08 | 1.50 | 2.00 | 0.035 | 0.020 | 19.00 ~ 22.00 | 24.00 ~ 26.00 | ||||||||||||||||||||||||||||

| S31608 | 06Cr17Ni12Mo2 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00~ 3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31603 | 022Cr17Ni12Mo2 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00-3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31668 | 06Cr17Ni12Mo2Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 10.00 ~ 14.00 | 16.00 ~ 18.00 | 2.00~ 3.00 | 一 | 一 | Ti≥5C | ||||||||||||||||||||||||

| S39042 | 015Cr21M26Mo5Cu2 | 0.020 | 1.00 | 2.00 | 0.030 | 0.010 | 24,00~ 26.00 | 19.00 ~ 21.00 | 4.00 ~ 5.00 | 0.10 | 1.20 ~ 2.00 | 一 | ||||||||||||||||||||||||

| S31708 | 06Cr19Ni13Mo3 | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00 ~ 20.00 | 3.00~4.00 | 0.10 | 一 | 一 | ||||||||||||||||||||||||

| S31703 | 022Cr19Ni13Mo3 | 0.030 | 0.75 | 2.00 | 0.035 | 0.020 | 11.00 ~ 15.00 | 18.00 ~ 20.00 | 3.00 ~ 4.00 | 一 | ||||||||||||||||||||||||||

| S32168 | 06Cr18Nil1Ti | 0.08 | 0.75 | 2.00 | 0.035 | 0.020 | 9.00 ~ 12.00 | 17.0 ~ 19.00 | Ti≥5C | |||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Kodhi yenhamba yakabatana | Brand | Kuumbwa kwemakemikari (chikamu chehuwandu)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | Zvimwe | ||||||||||||||||||||||||||

| 68 | S21953 | 022Cr19Ni5Mo3S2N | 0.030 | 1.30 ~ 2.00 | 1.00 ~ 2.00 | 0.030 | 0.020 | 18.00 ~ 19.50 | 4.50 ~ 5.50 | 2.50 ~ 3.00 | 一 | 0.05~ 0.12 | 一 | |||||||||||||||||||||||

| 70 | S22253 | 022Cr22Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 21.00 ~ 23.00 | 4.50 ~ 6.50 | 2.50~ 3.50 | 0.08~ 0.20 | 一 | ||||||||||||||||||||||||

| 71 | S22053 | 022Cr23Ni5Mo3N | 0.030 | 1.00 | 2.00 | 0.030 | 0.020 | 22.00 ~ 23.00 | 4.50 ~ 6.50 | 3.00~ 3.50 | 一 | 0.14~ 0.20 | 一 | |||||||||||||||||||||||

| Kuumbwa kwemakemikari emamwe mabhureki ari patafura akasiyana neayo eGB/T 20878 | ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Kodhi yekudzidzisa yakabatana | Brand | Kuumbwa kwemakemikari (chikamu chehuwandu)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Zvimwe | |||||||||||||||||||||||||||

| 78 | S11348 | 96C-13A | 0.08 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50 ~ 14.50 | 0.60 | - | - | Al:0.10~ 0.30 | ||||||||||||||||||||||||

| 92 | S11972 | 019Cr19Mo2NbTi | 0.025 | 1.00 | 1.00 | 0.035 | 0.020 | 17.50 ~ 19.50 | 1.00 | 1.75~2.50 | 0.035 | (Ti+Nb) [0.20+4 (C+N)] ~0.80 | ||||||||||||||||||||||||

| 97 | S11306 | 06Cr13 | 0.06 | 1.00 | 1.00 | 0.035 | 0.020 | 11.50 ~ 13.50 | 0.60 | 一 | 一 | |||||||||||||||||||||||||

| Kuumbwa kwemakemikari emamwe mabhureki ari patafura akasiyana neayo eGB/T 20878 | ||||||||||||||||||||||||||||||||||||

Mukobvu Wenguva

Upamhi hwendiro yesimbi isina tsvina:

1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm.

Non-ndiro kureba: 1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm inogona kutsanangurwa maererano nezvinodiwa nevatengi.

Cold rolling chikamu:

Stainless simbi ndiro inotonhora yakakungurutswa 2B (coil, strip, flat plate) character plate: 3 5mm—6mm 304/2B, 316L/2B.

Ukobvu: inotonhora yakakungurutswa 2B (0.1-6.0mm).

Pamusoro: 2B yakatsetseka pamusoro, BA.

8K girazi;Kudhirowa waya uye jecha;Snow sand;Stainless simbi yemunwe-isina ndiro.

Decorative panel: color plate, titanium plate, etching plate, oil polishing hairline plate (HL, NO.4), 3D three-dimensional plate, sandblasting plate, embossed plate.

Dhipatimendi rinopisa rinoputika: ndiro yesimbi isina tsvina inopisa inoputika No.1 (coil, flat plate).

Ukobvu: maindasitiri No.1 (3-159mm).

Pamusoro: 8K girazi pamusoro;Kudhirowa waya, titanium plating, jecha;Snow sand;Stainless simbi yemunwe-isina ndiro.